Imagine a logistics process where everything works seamlessly – sales forecasts are up to date, warehouse layouts are optimised, picking is smooth, and delivery routes and packing sequences are planned in seconds.

AI is not the future, it is the solution today.

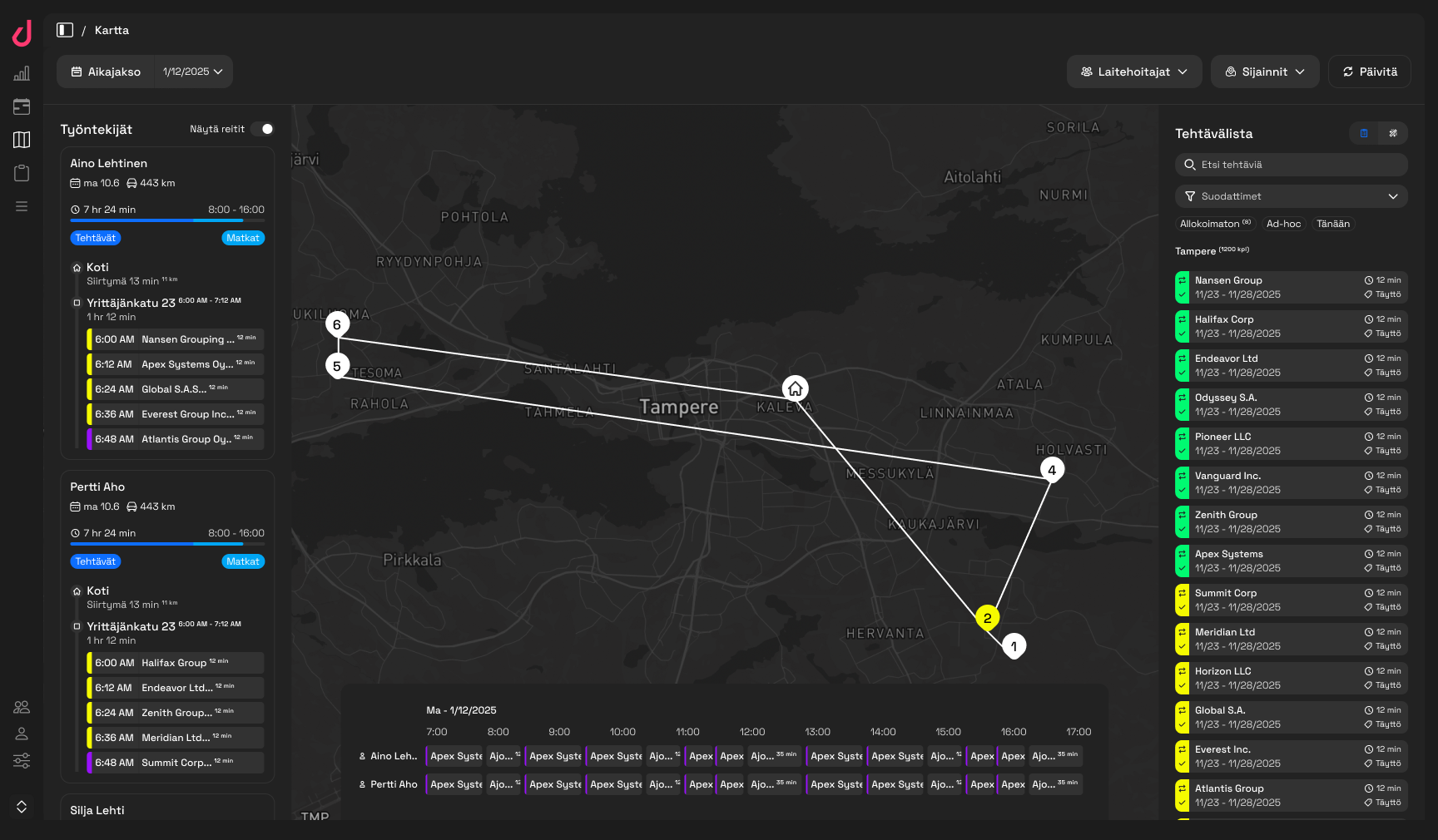

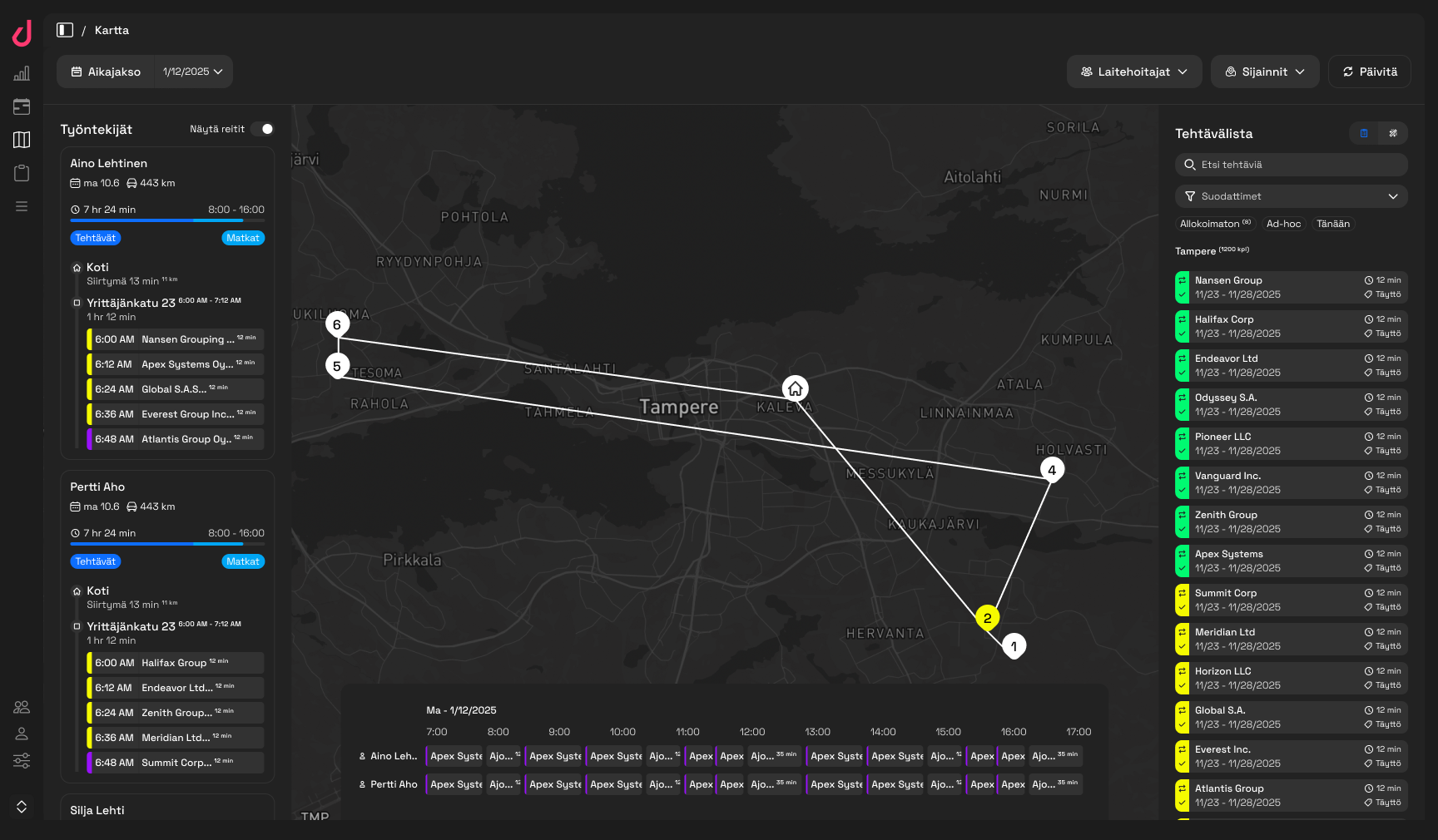

Optimising capacity and routes at once

Minimise waiting times, travel hours and kilometres and maximise efficient working time and fleet utilisation.

Allocator is an AI scheduler that takes into account real-life constraints such as vehicle capacities, allowed delivery windows, loading and unloading times as well as driver breaks.

Combined with Stackpacker, Allocator also automatically calculates the capacity required for orders and can intelligently combine separate orders into single deliveries. You can plan routes for your entire fleet at once or optimally integrate additional orders into standard routes.

Automatic packing motor - Stackpacker

An optimal packing order that minimises wasted space and streamlines the supply chain.

In logistics and warehousing, efficient packaging is crucial. Excessive wasted space, sub-optimal packing order and loading errors lead to higher costs and inefficiencies.

Dynamik’s Stackpacker packaging engine brings intelligence to packaging management. Our algorithm models products in three dimensions, taking into account the constraints of the transport space and the specific characteristics of the delivery, such as weight or fragility, as well as the order of delivery.

Optimising the overall logistics process

In logistics, each stage is interlinked. We are deep experts in the logistics process and offer customised optimisation solutions for other stages of the logistics process, such as sales forecasting, layout optimisation, shelving and picking optimisation.

An optimisation platform to support you at every phase

Sales forecasting

Versatile forecasting models can be used to predict the sales of products and take this into account when optimising the layout of the warehouse or for procurement management.

Warehouse layout optimisation

The layout of the warehouse can be optimised by taking into account product sales forecasts, the products that are often picked together, the capacity of the different storage locations and the time spent picking.

Automatic packing calculation

Packaging optimisation can be used to optimise transport (how do I maximise the use of available transport space?), packaging optimisation (how should these products be packed on a pallet/box/truck?) and warehouse optimisation (what type of storage space should each product be packed in?).

Optimising distribution

Dynamik Allocator creates optimal distribution routes for your entire fleet in seconds. The optimisation takes into account vehicle capacities, loading and unloading times, permitted and desired delivery times and driver breaks, among other things.

Different types of delivery products

Vehicles can have different transport capacities and driving times. You will receive intelligent alerts if the vehicles are over or under capacity, or if efficiency falls below recommended limits on a certain day.

Our customers

This optimization process can be thought of as a giant game of Tetris: a specific space needs to be fitted with the largest possible amount of different sized rectangular objects possible.

Mika Salmela

Director of Purchasing

,Kaskipuu

This optimization process can be thought of as a giant game of Tetris: a specific space needs to be fitted with the largest possible amount of different sized rectangular objects possible.

Mika Salmela

Director of Purchasing

,Kaskipuu